The GE Dryer Belt is a crucial component in the operation of a GE dryer. It is a rubber belt that connects the drum of the dryer to the motor, allowing the drum to spin and tumble clothes during the drying cycle.

The GE Dryer Belt is important because it is responsible for the rotation of the drum. Without it, the dryer would not be able to function properly and the clothes would not dry. It is also important because it can wear out over time and require replacement, which is why it is important to check and maintain the belt regularly to ensure that it is in good working condition.

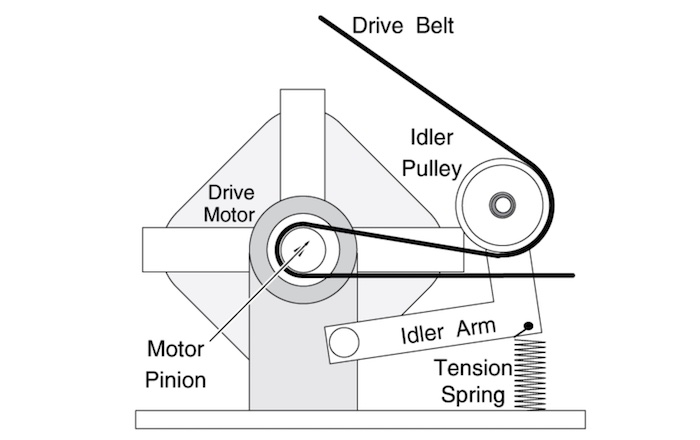

Using this GE Dryer Belt diagram, you should be able to properly maintain and fix the dryer belt when the time comes.

GE Dryer Belt Diagram

Below is a detailed diagram showing the parts of the GE dryer belt.

GE Dryer Belt-related Components Explained

Idler Arm

The idler arm on the GE dryer is a small, pivoting arm that helps to regulate the tension on the dryer belt. It is located near the back of the dryer and is connected to the motor and the dryer drum.

The idler arm helps to keep the dryer belt tight and in place, allowing the drum to rotate smoothly and efficiently during the drying cycle. If the idler arm becomes worn or damaged, it can cause the dryer to operate noisily or not start at all. In these cases, it may need to be replaced to restore the dryer to proper functioning.

Motor Pinion

The motor pinion is a small gear on the dryer’s motor that engages with the larger drum drive gear to spin the drum. It helps to transfer power from the motor to the drum, allowing the dryer to operate.

Idler Pulley

The idler pulley on a GE dryer is a small wheel that is attached to a spring and is used to provide tension to the drive belt. This tension is necessary to ensure that the belt remains tight and can effectively transfer power from the motor to the drum of the dryer. The idler pulley is typically located near the back of the dryer and is accessed by removing the dryer’s back panel.

Drive Belt

The drive belt on the GE dryer is a loop of rubber that connects the dryer drum to the drive motor, allowing the drum to spin during the drying cycle. It is an essential component of the dryer, as it enables the clothes to be tumbled and dried properly.

The drive belt can become worn or damaged over time, which can cause the dryer to not function properly or stop working altogether. It is important to periodically check and replace the drive belt as needed to ensure the dryer operates at its best.

Drive Motor

The drive motor on a GE dryer is the component that powers the drum and rotates it during the drying cycle. It is typically located under the drum and is connected to the drive belt. The drive motor is an electric motor that is controlled by the dryer’s control panel. It is responsible for providing the necessary power to turn the drum and move the clothes during the drying process.

Tension Spring

The tension spring on a GE dryer is a small, coiled metal spring that is located on the door of the dryer. Its function is to provide tension and support to the door, allowing it to open and close smoothly and securely.

It is typically attached to the door latch mechanism and is designed to maintain a consistent level of tension on the door as it is opened and closed. This helps to prevent the door from becoming loose or wobbly over time, and ensures that it remains securely closed during the drying cycle.

Drum Glides

Drum glides on your GE dryer are a type of plastic or nylon strip that is attached to the inner drum of the dryer. Their purpose is to provide a smooth and frictionless surface for the drum to rotate on, reducing wear and tear on the drum and the dryer’s motor. Drum glides help to ensure that the clothes in the dryer are evenly distributed and properly tumbled, allowing for efficient and effective drying.

Drum Rear Support Shaft

The drum rear support shaft is a metal rod that is located at the back of the dryer drum and provides support for the drum as it rotates during the drying cycle. This helps to ensure that the drum remains stable and balanced, reducing the risk of it becoming damaged or dislodged during operation.

Drum

The drum on your GE dryer is the large, rotating cylinder that holds the clothes during the drying cycle. It is made of metal and is typically located inside the dryer’s main housing. The drum is driven by a motor and is typically lined with a layer of heat-resistant material to prevent damage to the clothes. As the drum rotates, the clothes are tumbled and dried by the hot air flowing through the dryer.

How to Maintain the GE Dryer Belt

- Regularly inspect the dryer belt for signs of wear or damage, such as cracks or fraying.

- Clean the belt and surrounding area with a soft cloth and mild detergent to remove any debris or lint that could interfere with its performance.

- Check the tension of the belt to ensure it is properly adjusted. If it is too loose, it may slip or break, and if it is too tight, it can cause the dryer to overheat or damage the motor.

- If the belt shows signs of wear or damage, replace it immediately to avoid potential issues with the dryer.

- Follow the manufacturer’s instructions for proper installation and maintenance of the dryer belt.

- Regularly clean and maintain the dryer as a whole to prevent lint build-up and other issues that can affect the belt and its performance.