The Maytag Dryer Belt is a rubber belt that connects the dryer drum to the motor, allowing the drum to rotate and dry clothing. It is located on the back of the dryer, behind the dryer drum. The lifespan of the Maytag Dryer Belt varies depending on usage and maintenance, but it typically lasts between 3-5 years.

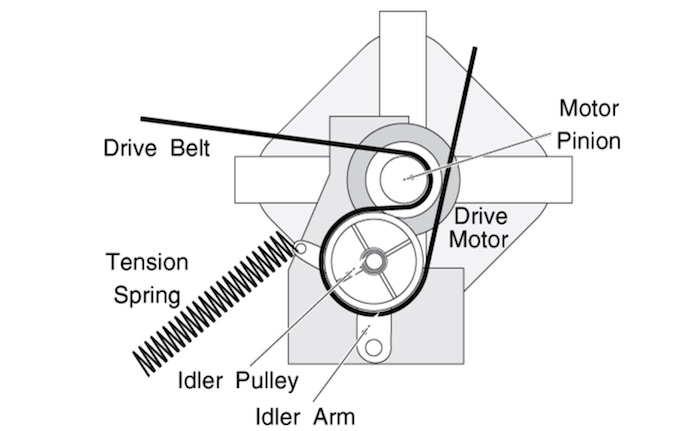

This article provides a detailed Maytag Dryer Belt Diagram that would make repairs, maintenance, and any other actions you want to take that involve the dryer belt a lot easier.

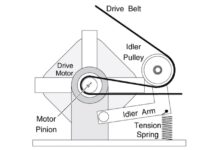

Maytag Dryer Belt Diagram

Maytag Dryer Belt & Related Components Explained

Drive Belt

The drive belt on the Maytag dryer is a long, thin belt that connects the dryer’s motor to the drum. It is responsible for turning the drum and allowing the clothes inside to tumble and dry.

The drive belt is made of rubber and can become worn or stretched over time, which can cause the dryer to not function properly. It is important to replace the drive belt when it becomes worn to ensure that the dryer continues to operate efficiently

Idler Pulley

The idler pulley is a small wheel that helps maintain tension on the dryer drum belt. It is located near the drive motor and is connected to the belt, allowing it to move freely and keep the belt taut as the drum turns.

This helps to ensure that the drum is able to spin smoothly and evenly, allowing the dryer to operate efficiently and effectively.

Drive Motor

The drive motor on a Maytag dryer is the component that powers the drum and tumbling action of the dryer. It is typically located on the back of the dryer and is connected to the drum via a belt or other mechanical means.

The drive motor is an essential component of the dryer and is responsible for providing the necessary force to turn the drum and dry the clothes.

Motor Pinion

The motor pinion is a small gear attached to the motor in a Maytag dryer. It engages with a larger gear on the dryer’s drive belt to rotate the drum and tumble the clothes. The motor pinion is an important component in the dryer’s operation and ensures that the drum is turning at the correct speed.

Idler Arm

The idler arm on a Maytag dryer is a small metal component that connects to the tensioning system of the dryer’s drive belt. It helps to keep the belt taut and in place as the drum rotates during the drying cycle. This ensures that the belt does not slip or become loose, which can cause damage to the drum and other components of the dryer.

The idler arm is typically located near the back of the dryer, behind the drum and drive motor. It is an essential component for maintaining the proper operation of the dryer.

Tension Spring

The tension spring on the Maytag dryer is a small, coiled metal spring that provides tension on the drum belt, allowing it to rotate smoothly and evenly during the drying cycle. It is located on the front of the dryer, typically near the bottom of the drum, and helps to ensure that the drum and belt remain properly aligned and functioning properly.

Drum Glides

The drum glides on your Maytag dryer are small, nylon or plastic pieces that are attached to the inside of the dryer drum. They are designed to reduce friction and allow the drum to smoothly rotate during the drying cycle. This helps to prevent damage to the drum and clothes and ensures efficient and effective drying.

Blower

The blower on a Maytag dryer is a fan that circulates air within the dryer to help dry the clothes. It is typically located near the back of the dryer and is typically driven by a belt or motor. The blower helps to distribute heat evenly throughout the dryer to ensure that the clothes are dried efficiently and evenly.

Drum Rollers

The drum rollers are small wheels located on either side of the dryer drum that help support and rotate the drum during the drying cycle. These rollers are typically made of durable materials such as rubber or plastic and are designed to withstand the weight and movement of the drum as it spins.

Over time, the drum rollers may become worn or damaged and will need to be replaced to ensure the proper functioning and performance of the dryer.

Lint Screen

The lint screen is a mesh screen located inside the dryer near the door. It is designed to catch lint and debris that is generated during the drying process. This helps to improve the efficiency of the dryer and prevent lint from clogging the venting system and causing potential fire hazards. It is important to clean the lint screen regularly to ensure that it is functioning properly.

Common Maytag Dryer Belt Problem and Fixes

Squeaking or squealing noise

This may be caused by a worn or loose belt. To fix, check the belt for any signs of wear or damage, and tighten or replace it if necessary.

Dryer not spinning or tumbling

This may be caused by a broken or worn belt. To fix, check the belt for any signs of damage, and replace it if there is a need to. You might also want to have a professional take a look at it.

Dryer not heating

This may be caused by a faulty heating element or thermostat. To fix, check the heating element for any signs of damage or obstruction, and replace it if necessary. Also, check the thermostat and replace if it is not functioning properly.

Dryer takes longer than usual to dry clothes

This may be caused by a clogged or blocked exhaust vent. To fix, clean the exhaust vent and make sure it is free of any obstruction.

Dryer not starting

This may be caused by a faulty door switch or start button. To fix, check the door switch and start button for any signs of damage or malfunction, and replace them if necessary.