Knowing the parts of the American standard kitchen faucet is very important. This helps when you’re installing the faucet or making repairs. Having knowledge of each component makes it easier for you to know how to use it properly.

In this article, you will find the American Standard Kitchen faucet diagram. We have also provided an explanation as how to each component of the faucet works

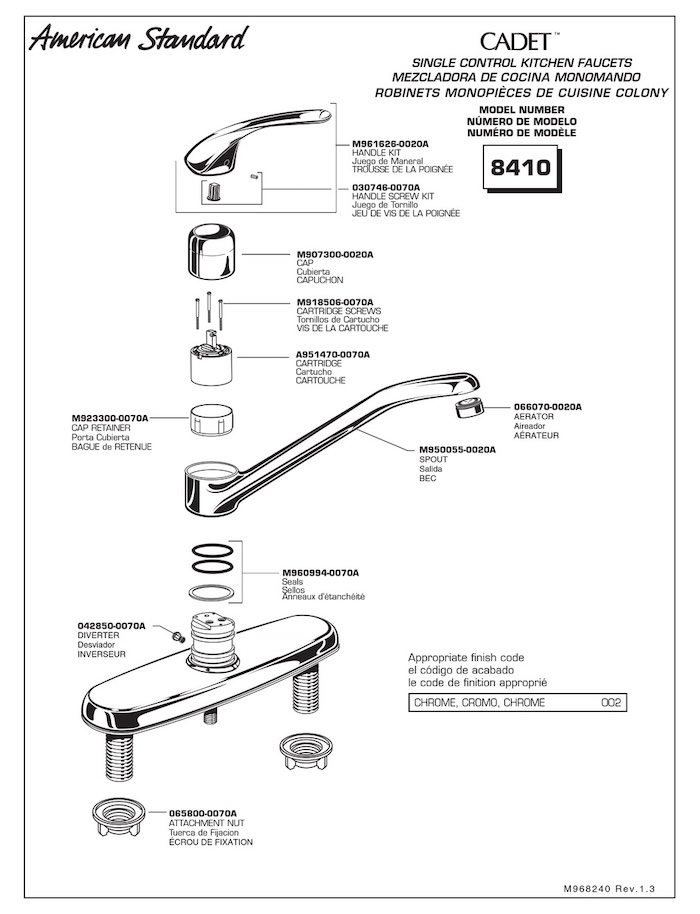

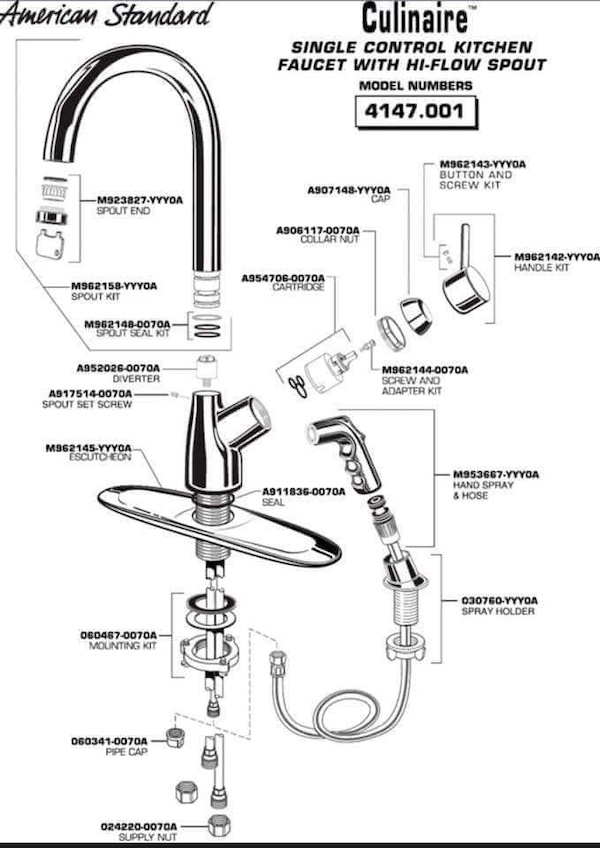

American standard kitchen faucet parts diagram

American standard kitchen faucet parts explained in detail

Aerator

The aerator is located at the tip of the kitchen faucet. It features small mesh screens on the faucet end that help to regulate water flow into multiple small streams to prevent splash and make the water flow more environmentally positive.

Spout Assembly

The spout assembly is designed to control the faucet spout. It consists of parts like the spout body, cap, and handles

Body

The body of the faucet is the part where hot and cold water is mixed before it gets to the spout. If the faucet is installed in a single-hole design, hot and cold water will be combined in a one-piece casing, which also houses the valve.

This setup is available in both one- and two-handle faucet designs. if you’re using a widespread body faucet, it would require three holes to install and the hot and cold water would be mixed together in a separate pipe.

Escutcheon

The escutcheon is a decorative feature that could also help if you need to maintain the aesthetic of the sink. Most new sinks come with a pre-installed number of holes.

If you’re not getting a brand-new sink, you would be stuck with all the holes that come with the sink. If you want to go for a single-hole faucet design but your sink features three holes or a widespread design, the escutcheon or baseplate can be used to cover the extra holes.

O-ring

The O=ring or adjusting rings works like a seal. it can be constructed of rubber, metal, or brass. The O-ring ensures that the joints of the faucet are watertight. The o-ring could also adjust the pressure on the spout assembly.

Mounting Nut

The mounting nut is a large nut that would not go unnoticed. Its function is to secure the kitchen faucet to the sink. There should be enough clearance between the wall and the sink to install the mounting nut with ease.

Washer

The washer of the faucet is a flat ring that connects the aerator to the faucet stems. It can be made of plastic, rubber, or metal. Washers also prevent leaking while allowing full water flow.

Spray Hose

The spray hose connects the hot water and cold water supply to the faucet. It also allows you to rotate the spray head as much as you want while using the faucet. Using an extendable spray hose with a double-bowl sink is a better option if you want to wash things on both sides

Different Types of Valves in American Standard Kitchen Faucets

Faucet valves come in four primary types; Cartridge, Compression, Ball, and Ceramic. The type of valve the faucet uses would affect its ability to regulate water flow and temperature. It also determines the longevity of the valve.

Compression

Compression valves are commonly found in older bathrooms as they’re among the first set of valves to be introduced since the beginning of plumbing. They are also one of the most affordable faucet valves you will come across. The compression faucet features individual hot and cold handles.

These allow the valves to control the water flow by the means of a part of the handle that compresses the water seal through a rubber washer. This process allows you to turn the water on and off by loosening the washer or tightening it.

Compression valves are prone to leaks so they will require constant maintenance. Luckily, these valves are the easiest to replace.

1. Ball Faucet

The ball faucet is the most common valve in kitchen faucets. They feature single handles at the top which move over a round ball-shaped cap at the base of the faucet spout to regulate water flow.

The ball inside the faucet body can be made of metal or plastic with chambers or slots inside it, which allow hot and cold water through the spout. Ball valves cost a bit more than regular valves and due to the moving parts, they tend to be more complicated to repair. Specialized tools and specific plumbing knowledge are needed to fix this valve type.

2. Cartridge Faucet

Cartridge valve faucets bear resemblance to compression faucets in terms of function but feature newer technology that makes them more durable. These faucets feature a movable stem cartridge that regulates water flow. Moving the faucet handle moves the sleeves of the cartridge, to block and align holes to regular the flow of water. This mimics the compression faucet but with a much smoother operation.

Cartridge faucet tends to be a bit pricier but is among the most durable of all valves. They should stand the test of time without leaks or faults. However, the cartridge seals do eventually wear out and would have to be replaced. Unlike other valve types, replacing the cartridge is a straightforward process that won’t require getting a technician.

3. Ceramic Disc Faucet

Ceramic disc faucets are modern-type faucets. They feature a wide cylindrical body and a single level containing a wide cartridge housing unit with two ceramic discs. The discs slide over one another to control the flow of water and temperature.

The motion of the two discs opening or restricting the pathway of water which control the water volume from the sprout. Ceramic discs are the highest-quality of sink faucets and can run for years without having to be replaced or repaired.

However, they are also the most expensive of faucet valves. While they would give you years of use, this doesn’t necessarily mean that they would last forever. With time, the rubber seals at the bottom o the cartridge will wear out and would have to be replaced.