The 5.3 Vortex engine is a popular choice for use in newer cars and trucks. It’s known for its high power output, minimal maintenance needs, and relatively low cost. However, if you’re looking to upgrade your old car or truck with a new engine but don’t know where to start, we’ve got some insight into how these parts work together!

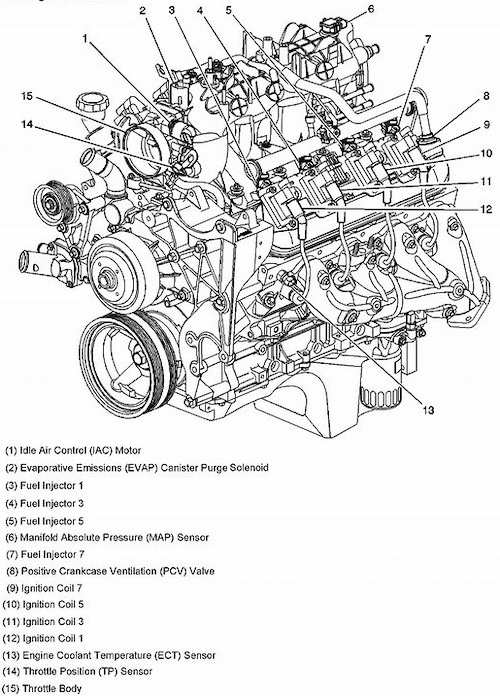

5.3 Vortex Engine Parts Diagram

A 5.3 vortex engine is a unique type of internal combustion engine that uses an intricate series of cogs and gears to harness the power of air molecules. The basic principle behind this design is simple: when you turn a tire, the air inside it moves faster than outside air around it. This creates a vacuum (or low pressure) within your car’s tires, which means they have less resistance than normal when they push against floorboards or bumpers on rough terrain—and can therefore generate more power than other types of engines!

What makes this type of car so special? Well, there are several advantages to having one: firstly, because there are fewer moving parts involved in running such an engine versus others like piston-based models; secondly but perhaps most importantly though is how easy it makes driving on difficult terrain such as snow since all you need do is just put your foot down; thirdly fourthly fifthly sixth, etc.

5.3 Vortex Engine Parts Explained

The 5.3 Vortex Engine is an ideal engine for small cars, SUVs, and lightweight trucks. It’s also known as the Mitsubishi 4G63 and it has been used in many vehicles since its introduction in 2002. In fact, it’s been used in over 80% of all vehicles sold since then!

The 5.3 vortex engine was developed by General Motors for full-size SUVs.

The Block

The block is the main part of an engine. It holds all the parts together and is made of cast iron. The block is what allows your car to move, so it’s important to keep it in good shape. If you could see inside your engine, you would see that there are many different pieces made up of this one central piece (the block).

Pistons and Rods

Piston and rod assemblies are the main components of a Vortex Engine. They increase the efficiency with which heat energy is transferred, allowing for higher power output in a smaller space.

The piston and rod assembly house two pistons: one that moves up and down inside its cylinder, and another that moves back and forth across its cylinder walls (or “valves”).

These move in unison when you turn your engine on so they create an alternating motion between them—the same kind that happens when you turn on your car’s windshield wipers or fan blades.

The purpose of these assemblies is to help keep gasses moving efficiently as they pass through each valve-piston pair without being blocked by any friction caused by oil buildup on those parts’ surfaces; this prevents air bubbles from forming within those gasses because then there would be no place left where anything could escape through without having to stop prematurely due to lackluster performance levels!

Cylinder Heads

Cylinder heads are the part of your engine that sits above your pistons and below the cylinders. They have many different functions, including:

- Collecting and directing fuel into each cylinder

- Supplying lubrication to the moving parts in each cylinder (piston rings, etc.)

- Distributing exhaust gasses from each cylinder through an exhaust manifold to help with cooling

Intake Manifold

The intake manifold is the first part of the engine that air enters. It’s made up of a series of tubes that connect to the cylinders and mix air with fuel before it enters your engine. The intake manifold helps distribute heat evenly throughout all four cylinders, which is important because it prevents deposits from forming on piston walls, which could cause damage or even seizure if left unchecked for too long.

This piece also allows for easy access for maintenance personnel when needed — as well as providing an opportunity for customization depending on how much room you want at certain points along its length (for example large intakes will require larger diameter tubing).

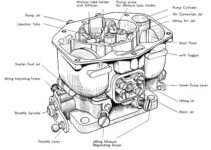

Fuel and Intake Components

The fuel system is the heart of your engine. A good quality fuel pump should be able to deliver consistent pressure, with no leaking or hard starting issues. Look for a high-quality, durable pump that will last you many years.

Also, make sure to install high-quality fuel injectors that are not only easy to clean but also powerful enough for any given engine application (more on this later). For example: if you have an old car with low compression ratios then you’ll probably need smaller injectors than you’d do for an automatic transmission vehicle where everything is more efficient from a design perspective.”

Ignition Components

The ignition components are the first to be checked. These include the coil, distributor, and spark plugs. The coil is a device that sends an electrical current through all of the cylinders in order to spark combustion within each cylinder.

This causes fuel to mix with air and ignite at an optimal rate for optimal performance. A bad or worn-out coil can cause problems like misfiring or no power output at all from your engine; if it’s not replaced promptly, this could lead to further damage over time as well as increased wear on other parts (such as pistons).

The distributor is what makes sure that all of those wires come together at just the right place so they can transfer their energy into motion throughout our engines’ pistons/rods/etc., thus causing them all kinds of fun stuff like turning wheels against gravity! When something goes wrong with this part either physically or electrically (like corrosion), then we’ll need new ones installed quickly before anything else breaks down too badly.

Engine and Engine Bay Components

The engine and engine bay components are the heart of a Vortex engine. They are responsible for all the power that makes your vehicle go, so it’s important to keep them running efficiently and safely.

The following is a list of common parts that make up an engine:

Engine mounts – These keep the rotating assembly from moving around in relation to its supporting members (such as subframes). They provide support for connecting rods, crankshaft bearings and other components near these moving parts. If there are no engine mounts installed properly at all times then this could cause damage to these crucial components over time due to excessive stress being placed on them by vibrations while driving down roads at high speeds (which could eventually result in failure).

Alternator – This device generates electricity through mechanical means rather than using batteries like most other types do today; however instead of generating direct current (DC), it produces alternating current (AC) which means that instead each pole has two opposite voltages – positive (+) vs negative (-) respectively

Exhaust Components

Exhaust components include the exhaust manifold, exhaust pipes, and the exhaust system. The exhaust manifold connects to cylinder heads at each end of an engine. It is a device that directs hot gasses away from cylinders and into a muffler or tailpipe. The muffler reduces noise from the engine by directing it away from occupants in your vehicle’s cabin while also decreasing drag on your vehicle’s tires, which improves fuel economy and performance when you drive faster than usual (because there’s less resistance).

Conclusion

With the Vortex engine, you can get the power of a larger engine in a compact package. You’ll also save money and have less maintenance than with other smaller engines.