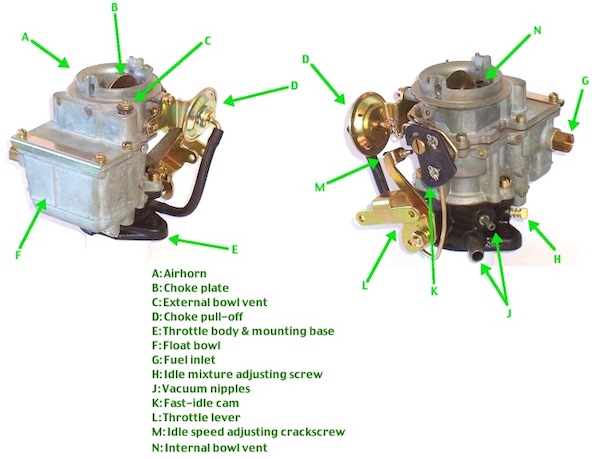

If you’re looking to replace your Briggs and Stratton carburetor and need some guidance on the various components of the carburetor and the functions of each, then this article is for you. We’ll show you a diagram of the parts of a Briggs and Stratton carburetor, so you can better understand how to fix or correctly replace a broken carburetor unit.

Briggs & Stratton Carburettor Parts Diagram

Briggs & Stratton Carburettor Parts Explained

Needle valve and seat

The needle valve is a small piece that seals the fuel flow through the carburetor and controls how much fuel enters your engine. The needle seat is what sits on top of this assembly, holding it in place (and preventing it from leaking). The two parts are not interchangeable—you can’t use an old carburetor with a new one if you need to change out one or both components!

Air filter base

The air filter base is located on the side of the carburetor and supports the air filter. It also holds the cover in place, which helps to ensure that dirt and debris don’t enter into your engine when you start it up.

Air filter cover

The air filter cover is the most important part of your Briggs & Stratton Carburettor. It protects the air filter from dirt and debris, as well as prevents water from entering it. You can remove this part to clean the air filter easily, but make sure that you do not lose any parts while doing so!

Air vent

The carburetor air vent is a tube that allows air to pass through. It’s part of the carburetor assembly, which helps prevent fuel starvation and overflow.

Carburetor gasket kit

A gasket kit is a set of gaskets for a carburetor. They are used to seal the carburetor so that it doesn’t leak fuel when you turn on your lawn mower or ride in the car. Gaskets can be made from rubber, plastic, or neoprene.

If you do not have the air filter cover on, then dirt and debris can enter your carburetor. This will prevent it from working efficiently, and may even cause damage to some of its partsThe air filter base is a plastic component that supports the air filter and holds it in place.

It also has a metal plate on one side that connects to the carburetor. The carburetor air vent prevents fuel from overflowing into the engine by allowing excess pressure to escape from the tank. It’s made of plastic, metal, or rubber depending on your car’s make and model. Gaskets come in many different shapes and sizes, depending on their purpose.

Primer bulb assy

The primer bulb assy is a part of the carburetor, which is used to prime the carburetor. It pumps fuel into the carburetor and makes it ready for use by injecting air or vapor into it, which causes an explosion when mixed with gasoline vapors coming from inside your engine’s combustion chamber.

The primer bulb assy may have one or more openings at its base that allow gas from pressurized sources like an air compressor or fuel pump to enter while simultaneously creating pressure within these openings so that they remain sealed off from outside elements such as moisture and dirt particles (which could cause issues later on downstream)

Fuel line kit

The fuel line kit is used to connect the fuel line to the carburetor. It contains several parts including a filter, a base, and a cover.

You can replace the fuel line on your lawnmower with a new one if it is cracked or damaged. The new line will also help you to prevent gas leaks as it is made of high-quality materials and features durable construction.

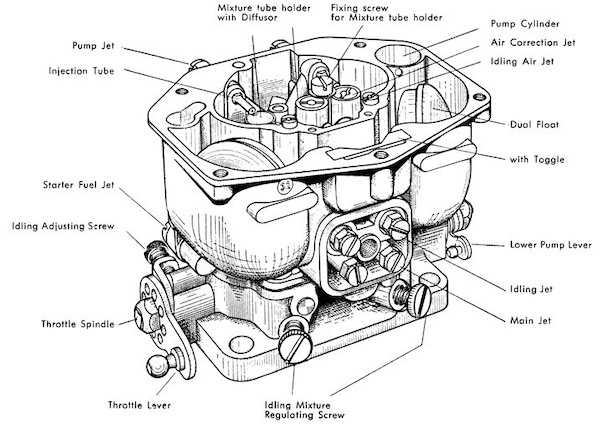

Metering System

The metering system is the component in charge of the precise air-fuel ratio since it regulates the fuel flow into the nozzle. It is made up of a measuring orifice and a fuel discharge nozzle.

It is the pressure difference between the air and fuel that causes the venturi to create a low-pressure field across the throat as air flows through it. After that, the fuel is released into the atmosphere. The amount of fuel released is regulated by the metering orifice and a discharge hole at the fuel discharge nozzle’s tip.

Throttle Return Check

Since a very high intake manifold vacuum is produced by a running engine at full throttle, this is the case. During v/v overlap, the exhaust will be sucked into the engine intake. Misfiring or a stoppage may result from the intake chart becoming diluted.

Anti-dieseling Solenoid

Since today’s pollution controls require higher operating temperatures, the combustion chamber can get very hot in specific areas. These high temperatures trigger chamber pre-ignition. These days, most engines have an anti-dieseling solenoid built into the carburetor to stop the engine from starting prematurely.

Choke Valve

A carburetor’s choke valve regulates airflow to the fuel/air combination. Its function is to regulate the amount of air present in the mixing chamber.

This valve is generally kept in a partially open position but is fully opened whenever a more concentrated blend is called for. To obtain the enriched mixture, the chamber’s air intake is sealed. This is because there is less air in the chamber, causing a greater proportion of fuel to be present in the mixture.

During the colder months, when starting an engine can be a real challenge, this valve comes in especially handy. Its purpose is to deliver a high-density air-fuel mixture to the engine’s combustion chamber.

Float Chamber

The continual supply of fuel is aided by float chambers, which are storage tanks for fuel. The fuel in the float chamber is constantly monitored by the floating valve.

The fuel supply is cut off when the float moves to the top of the fuel tank. In addition, the float will travel downward as the fuel level in the chamber drops. When you do this, the fuel supply valve opens, letting more gas into the float tank.

Conclusion

There are many versions of the carburetor. But the basic mechanism is the same for all of them. If you have an old Briggs & Stratton engine, then you can upgrade it to modern technology by replacing these parts with new ones.